Why Is It Important to Maintain Turbines on Schedule?

Regular turbine maintenance is essential to ensure optimal performance, prevent major failures, and extend equipment lifespan. Without proper servicing, turbines can lose efficiency, consume more fuel, and risk costly breakdowns. Scheduled maintenance helps detect and resolve issues early, reducing operating costs and ensuring system safety. Additionally, it ensures compliance with industry standards, avoiding legal risks. Investing in routine turbine maintenance is the key to stable, cost-effective, and reliable operations.

Turbines play a crucial role in industrial systems, marine applications, and power plants. Regular maintenance ensures optimal performance, extends the lifespan of equipment, and prevents costly failures. Below are the key reasons why scheduled turbine maintenance is essential.

1. Maintain Stable Performance

Turbines operate under high pressure and temperature conditions, leading to gradual wear and tear. Without proper maintenance, they may lose efficiency, consume more fuel, and reduce overall output capacity.

2. Prevent Major Breakdowns

Neglecting turbine maintenance can result in serious issues, such as:

✅ Imbalance of turbine blades

✅ Lubrication oil leaks

✅ Bearing and shaft damage

✅ Blade fractures causing catastrophic failures

These problems not only damage equipment but also disrupt operations and lead to high repair costs.

3. Reduce Operating Costs

Regular inspections help detect and fix minor issues before they escalate into major failures, avoiding unexpected repairs and downtime. Additionally, well-maintained turbines operate efficiently, leading to lower fuel consumption and reduced operating costs.

4. Ensure Safety for Equipment and Personnel

A malfunctioning turbine can cause fires, oil leaks, or complete system shutdowns. Routine maintenance helps ensure safe and stable operation, preventing hazardous incidents.

5. Comply with Industry Regulations and Standards

Most industries have strict guidelines on turbine maintenance. Adhering to a scheduled maintenance plan helps businesses meet technical standards, avoid legal risks, and optimize operational efficiency.

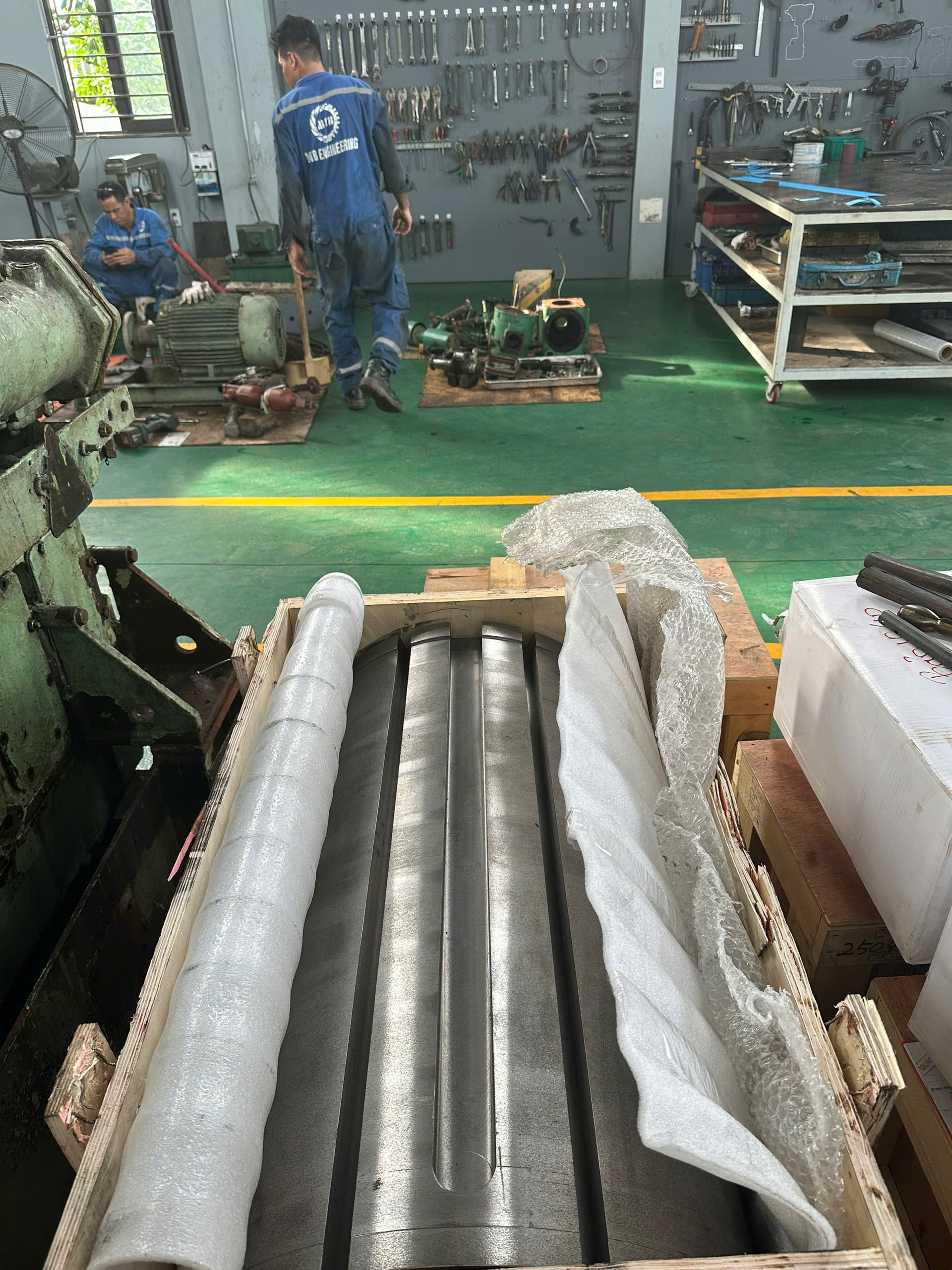

Professional Turbine Maintenance Services

We provide comprehensive turbine maintenance and overhaul services, including:

✔ Inspection & troubleshooting

✔ Cleaning and replacement of worn-out components

✔ Dynamic balancing and efficiency optimization

✔ Safety checks and operational testing