DYNAMIC BALANCING SERVICE FOR ROTATING EQUIPMENT

Dynamic balancing is a crucial process aimed at reducing vibration, noise, and wear in rotating equipment. Imbalance can lead to severe damage, reduced equipment lifespan, and increased operational costs. With modern technology and an experienced team of technicians, we provide professional dynamic balancing services to optimize performance and ensure safe operation.

Why is Dynamic Balancing Necessary?

-

Reduce Vibration: Prevents damage to bearings, shafts, and rotating components.

-

Extend Equipment Lifespan: Minimizes wear and tear, reducing the need for repairs and replacements.

-

Improve Efficiency: Lowers energy consumption, allowing equipment to operate more smoothly.

-

Reduce Noise: Creates a safer and more comfortable working environment.

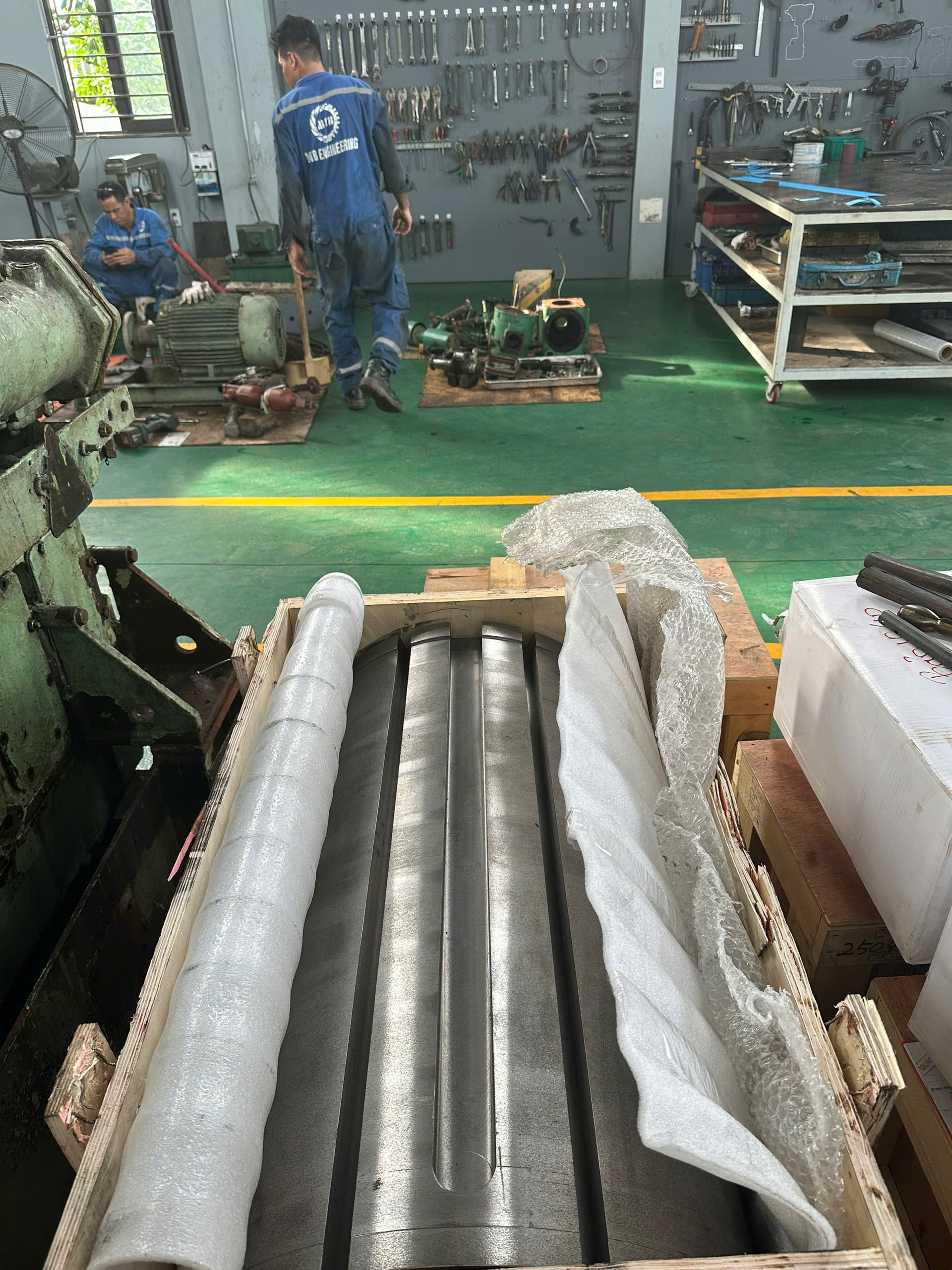

Equipment Requiring Dynamic Balancing

We offer dynamic balancing services for various rotating equipment, including:

-

Turbines

-

Industrial Fans

-

Centrifugal & Screw Pumps

-

Electric Motors & Generators

-

Rotors, Shafts, Flywheels

-

Industrial Gearboxes

Service Process

-

Inspection and assessment of equipment condition

-

Measurement and analysis of imbalance using advanced instruments

-

Execution of dynamic balancing according to int

ernational standards

ernational standards -

Reinspection and delivery of equipment with a detailed report