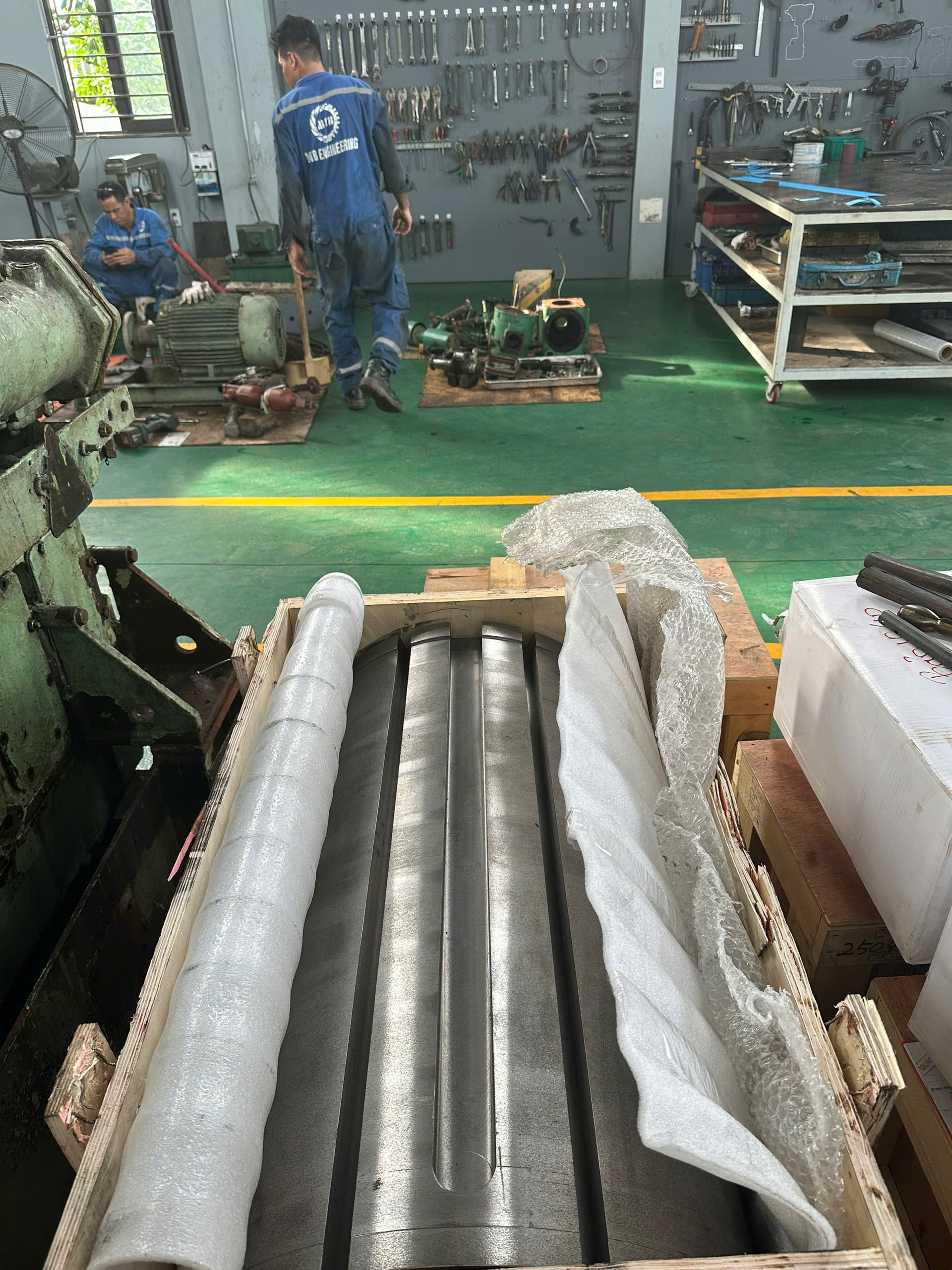

REAMER BOLTS HOLE BORING AND FABRICATION

Project Summary

MTB Engineering received an urgent request from a shipowner to replace reamer bolts and perform precision boring of reamer bolt holes for the Intermediate and Main Engine (ME) flywheel flanges. The entire operation was conducted under the strict supervision of an NKK surveyor. A service engineer was promptly dispatched from Hai Phong City, Vietnam, to the site for inspection and execution of the work.

Vessle name: AN HAI STAR

Type of VS: GENERAL CARGO

IMO No: 9261009/ 12500 DWT

Work to be done: BORING THE REAMER BOLTS HOLE AND FABRICATING THE REAMER BOLTS

Scope of Work & Results

- Bored all reamer bolt holes for the Intermediate flange and five holes on the ME flywheel flange.

- Supplied raw materials and fabricated new reamer bolts, which were approved by the on-site NKK surveyor.

-

Bolts were conditioned in dry air for 4 hours prior to installation to ensure proper fitting and material stability.

- Project Duration: 5 days

Note: All procedures and workmanship were strictly monitored and approved by the on-site NKK surveyor to meet classification standards.