Oil Tanker Shaft bearing recondition

Project: Shaft bearing recondition

Vessel: Kenzi 05

Type of VS: Oil Tanker

Customer: coming from Syria

Working place: Nosco Shipyard

Completion time: 7 days

Service type: Normal

Done by: MTB engineer Team

Ship problem

Intermediate shaft bearing was hot in running test. It need to be inspected and repaired.

MTB action

Recently, an Oil Tanker of the Sirian customer experienced the heat on its intermediate shaft bearing. MTB Co., Ltd was informed to carry out an inspection on the bearing shell and pedestal to propose a solution.

Upon inspection, it was determined that the babbit layer of ship shaft bearing worn down. Its repair would be required.

.png)

Solution

MTB proposed to complete the machining in 5 – 7 days on-site. Our engineer team was set to work repairing it at Nosco shipyard.

Rectifying damaged babbit layer of ship shaft bearing:

MTB Engineer carried out the re-babbitting process by metal spray method.

.png)

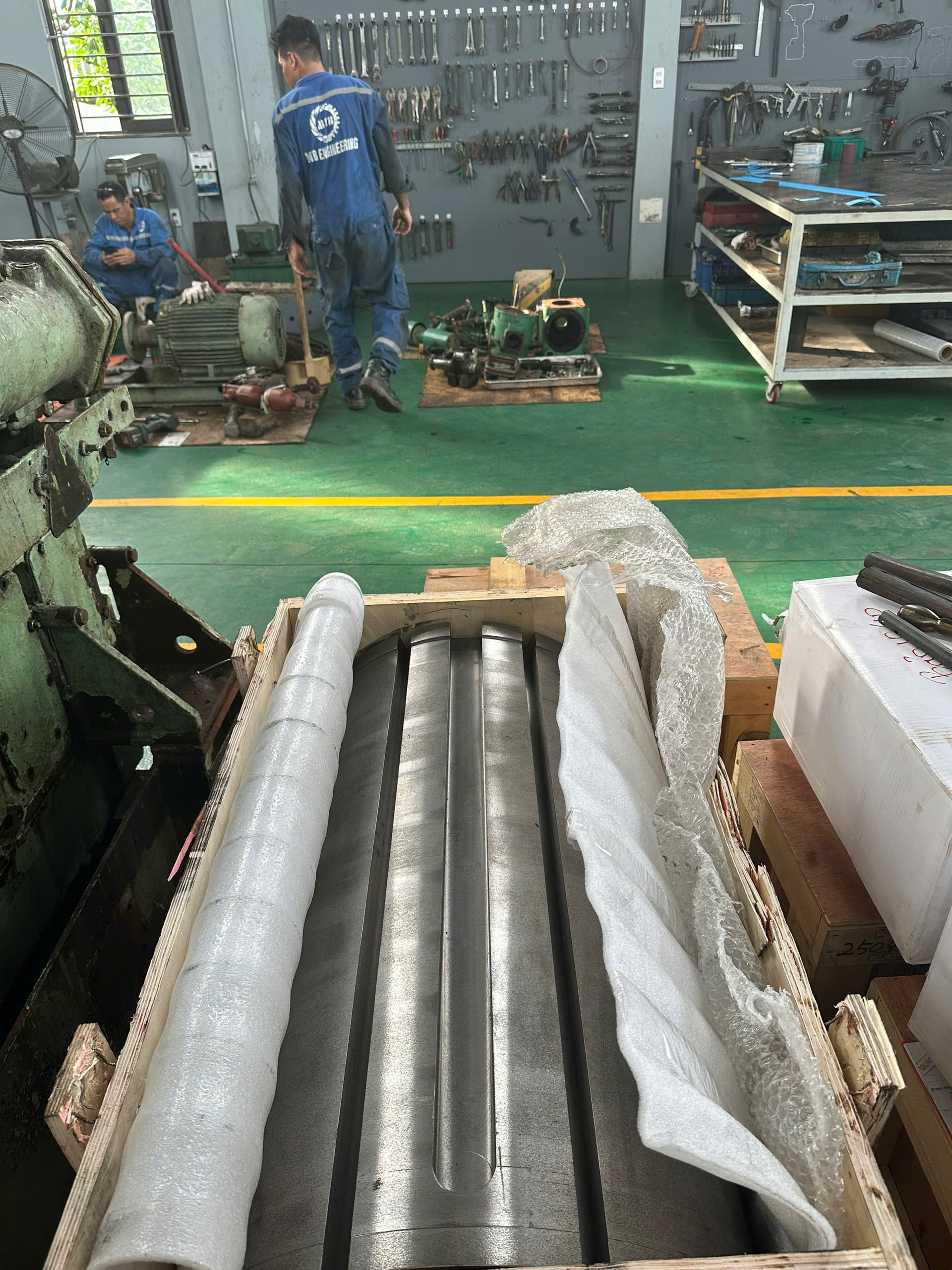

Bearing machining:

Bearing machining was proceeded on the highest quality machine tools. It was correctly removed to original dimension.

.png)

Installation, Re-check & Adjusting:

Correct bearing was be reinstalled. The load - bearing was rechecked and adjusted together with the realignment of shafting system.

.png)

Final check:

Final check of the bearing and the engine were carrefully made. The engine in running test and bearing were in good condition, the crank shaft deflection also was in good range.

.png)

For requesting more recondition of intermediate bearing and propeller shaft stern tube bearing, please feel free to contact us 24/7