Maintenance of Marine Governors

The governor is a critical component of a ship's engine system, ensuring stable and efficient engine operation. Regular maintenance of the governor not only extends its service life but also ensures safety and operational performance of the vessel.

Governor Maintenance Procedure

-

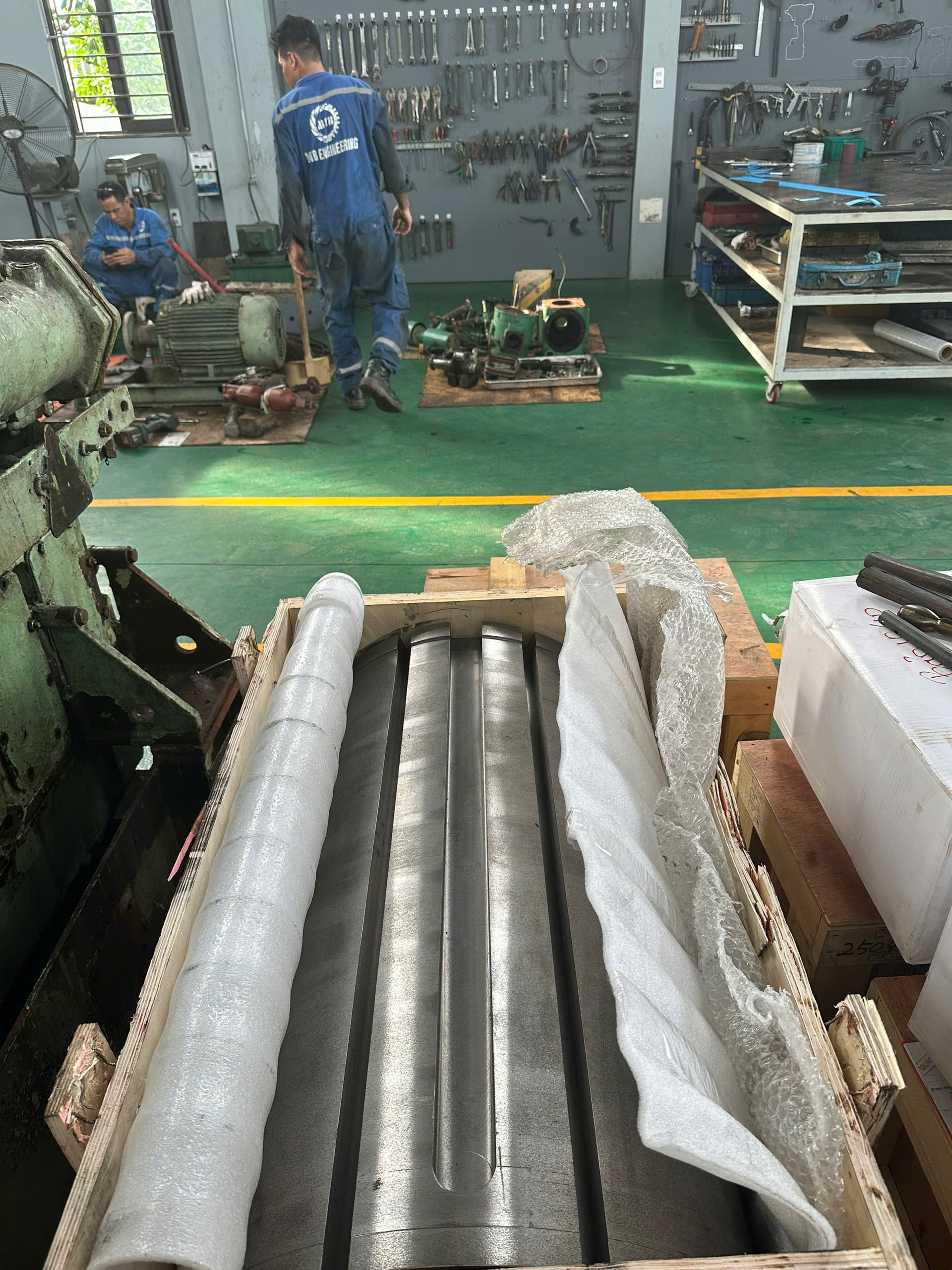

Disassembly and Inspection of Components

The maintenance process begins with the complete disassembly of the governor. This requires skilled technicians and the use of appropriate tools to avoid damaging the equipment. Each component is carefully inspected to assess its current condition:- Mechanical inspection: Evaluate wear, cracks, or deformation.

- Functional inspection: Ensure all components operate as designed.

-

Cleaning the Components

After disassembly, all parts are thoroughly cleaned using specialized cleaning solutions. This step removes oil residue, dirt, and accumulated deposits from operation. -

Replacement of Damaged Components

Any damaged or non-compliant parts are replaced with genuine components. Using standard-compliant parts not only ensures quality but also enhances the durability and efficiency of the governor. -

Reassembly and Calibration

Once cleaned and repaired, the governor is reassembled following precise technical procedures. The unit is then tested and calibrated on a test bench to:- Evaluate performance.

- Verify the accuracy of speed regulation.

- Detect and resolve any technical issues.

-

Reinstallation and Operation

After confirming optimal performance on the test bench, the governor is reinstalled into the ship’s engine system. A final operational check is conducted onboard to ensure compatibility and flawless operation.

Benefits of Governor Maintenance

- Increased reliability: Reduces the risk of failure during operation.

- Optimized performance: Ensures stable engine operation and fuel efficiency.

- Extended equipment lifespan: Lowers long-term replacement costs.

- Enhanced safety: Prevents potential incidents that could impact the vessel’s voyage.

Conclusion

Governor maintenance is an essential part of marine engine system upkeep. Adhering to the correct procedures not only maintains operational efficiency but also contributes to safety and cost-effectiveness in ship operations. Always choose reputable maintenance services and genuine components to ensure the highest quality for your equipment.